COMMON TRADE NAMES: Super 17 Chrome, Super 17Cr, SM17CRS®

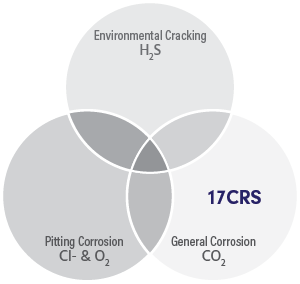

17 Chrome may be considered as a cost-effective alternative to duplex stainless steels such as 22 Chrome for higher pressure and temperature HPHT conditions. However, all environmental factors, including H2S, CO2 , temperature, pH, and chloride concentration, should be considered before final material selection.

17 Chrome is not recommended for sour service.

| C | Cr | Ni | Fe | Mn | Si | Mo | Cu | V |

|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | 16 - 18 | 4 - 5.5 | BAL | ≤ 0.5 | ≤ 0.05 | 2 - 3 | 2 - 3 | ≤ 0.1 |

| PROCESS | DESCRIPTION |

|---|---|

| Steel Making | Made by electric furnace (EF) or basic oxygen furnace (BOF) |

| Pipe Making | Manufactured by traditional hot tube manufacturing processes |

| Heat Treatment | Quenched and tempered |

| Grade | Yield Strength ksi | Tensile Strength ksi | Elongation % | Hardness HRC | NACE MR0175/ISO 15156 H2S Sour Service Limits |

||

| min | max | min | min | max | |||

| 125 | 125 | 145 | 130 | Function of specimen size | 38 | Not recommended for sour service | H2S ≤ 1.5 psi, pH ≥ 3.5 |

| 70°F | 300°F | 400°F | ||

|---|---|---|---|---|

| Density | lbs/in3 | 0.28 | 0.28 | 0.28 |

| Thermal Expansion | X10-6/°F | 6.1 | 6.1 | 6.1 |

| Elastic Modulus | psi x 106 | 28.1 | 27.3 | 26.7 |

| Poisson Ratio | 0.32 | 0.32 | 0.29 | |

| Yield Strength De-Rating | % | 100 | 88 | 85 |

MIN OD: 2-1/16″ (2.0625″)

MAX OD: 10-3/4″ (10.750”)

MAX WALL THICKNESS: 1.925”

LENGTHS: R1, R2, R3

END FINISH: Plain end, Premium threads, & API threads

Standard & Non-Standard Sizes Available.

Manufactured Material Available as Quickly as 1 Week.

Non-Standard Mill Quantities Accommodated

Our expert metallurgy team is here to help.

Contact Us