COMMON TRADE NAMES: 13CRS, SM13CRS®, Super 13CR, CR13S, 13CrSS, 13Cr-HP2, HP2, Hyper II, Hyper 2

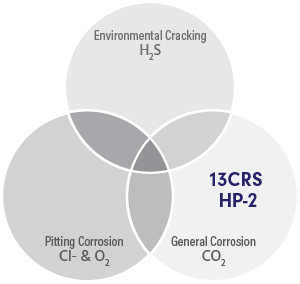

Super 13 Chromes offer improved mechanical properties and increased resistance to the effects of CO2 , H2S, chlorides, pH, and temperatures when compared with standard 13 Chrome. The higher strength and temperature resistance, relative to 13 Chrome L80, allow their use in deeper wells with high pressure and high temperature (HPHT) conditions, as downhole tubular components, packers, and other subsurface equipment. Super 13 Chromes also provide increased resistance to H2S and chlorides relative to Modified 13 Chrome, allowing for use in mild sour environments.

UNS S41426 is included in NACE MR0175/ISO15156 Table A.19, which provides a recommended limit of 1.5 psi partial pressure H2S. API 5CRA/ISO13680 classifies it as Group 1, Category 13-5-2 alloy acceptable for sour service, in the 95 ksi yield strength condition.

Per API 5CRA Table A.2

| C | Cr | Ni | Fe | Mo |

|---|---|---|---|---|

| 0.02 | 13 | 5 | BAL | 2 |

| PROCESS | DESCRIPTION |

|---|---|

| Steel Making | Made by electric furnace (EF) or basic oxygen furnace (BOF) |

| Pipe Making | Manufactured by traditional hot tube manufacturing processes |

| Heat Treatment | Quenched and tempered |

API 5CRA / ISO 13680 Group 1 Category 13-5-2

| Grade | Yield Strength ksi | Tensile Strength ksi | Elongation % | Hardness HRC | NACE MR0175/ISO 15156 H2S Sour Service Limits |

||

| min | max | min | min | max | |||

| 80 | 80 | 95 | 90 | Function of specimen size | 27 | Table A.19 | H2S ≤ 1.5 psi, pH ≥ 3.5 |

| 95 | 95 | 110 | 105 | 27 | |||

| 110 | 110 | 140 | 115 | 32 | 110 Grade not recommended for sour service | ||

| 70°F | 200°F | 350°F | ||

|---|---|---|---|---|

| Density | lbs/in3 | 0.28 | 0.28 | 0.28 |

| Thermal Expansion | X10-6/°F | 5.9 | 5.9 | |

| Elastic Modulus | psi x 106 | 29.3 | 28.7 | 28.2 |

| Poisson Ratio | 0.3 | 0.3 | 0.3 | |

| Thermal Conductivity | Btu/ft h °F | 9.1 | 9.7 | 10.7 |

| Specific Heat | Btu/lb °F | 0.1 | 0.11 | 0.12 |

| Yield Strength De-Rating | % | 100 | 91 | 87 |

MIN OD: 2-1/16″ (2.0625″)

MAX OD: 10-3/4″ (10.750”)

MAX WALL THICKNESS: 1.925”

LENGTHS: R1, R2, R3

END FINISH: Plain end, Premium threads, & API threads

Standard & Non-Standard Sizes Available.

Manufactured Material Available as Quickly as 1 Week.

Non-Standard Mill Quantities Accommodated

Our expert metallurgy team is here to help.

Contact Us