COMMON TRADE NAMES: CRA 2550E, CRA2550, 25%CR50%Ni, SM2550®

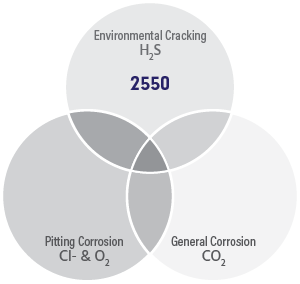

The high nickel and molybdenum content of 2550 extends the sour service limits of nickel alloys while also providing excellent resistance to chlorides and dissolved oxygen. Therefore, it is commonly used for downhole tubular components, packers, and other subsurface equipment in severely sour wells with high-pressure and high-temperature (HPHT) conditions, saltwater injection wells, and Acid Gas Injection (AGI) wells. However, all environmental factors, including H2S, CO2 , temperature, pH, and chloride concentration, should be considered before final material selection.

For sour service applications, 2550 is classified in MR0175/ISO15156 as a type 4d alloy, with no restrictions to a partial pressure of H2S below 300°F and resistant to 300 psi H2S at 425°F.

CRA 2550E (UNS N06255) is a premium, electro-slag re-melted version of alloy 2550. The performance and consistency are enhanced through tightly controlled compositional limits and microstructural cleanliness. CRA 2550E has excellent hydrogen embrittlement resistance at all standard strength levels.

| C | Cr | Ni | Fe | Mn | Si | Mo | Cu | P | S | Ti | W |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ≤ 0.03 | 23 - 26 | 47 - 52 | BAL | ≤ 1 | ≤ 1 | 6 - 9 | ≤ 1.2 | ≤ 0.03 | ≤ 0.03 | ≤ 0.69 | ≤ 3 |

| PROCESS | DESCRIPTION |

|---|---|

| Steel Making | Made by electric furnace process or blast furnace followed by Vacuum Oxygen Decarburization (VOD) process or Argon Oxygen Decarburization (AOD) Process |

| Pipe Making | Manufactured by traditional tube manufacturing processes, High strength tubulars should be furnished in cold worked condition |

| Heat Treatment | Solution Annealing Process before final cold drawing |

API 5CRA / ISO 13680 Group 4 Category 25-50-6

| Grade | Yield Strength ksi | Tensile Strength ksi | Elongation % | Hardness HRC | NACE MR0175/ISO 15156 H2S Sour Service Limits |

||

| min | max | min | min | max | |||

| 110 | 110 | 140 | 125 | 11 | 35 | Table A.14 | No limit ≤ 300°F, Refer to table for temperatures up to 400°F |

| 125 | 125 | 150 | 130 | 10 | 37 | ||

| 140 | 140 | 160 | 145 | 9 | 38 | 140 Grade not recommended for sour service | |

| 70°F | 250°F | 350°F | 450°F | ||

|---|---|---|---|---|---|

| Density | lbs/in3 | 0.297 | 0.296 | 0.295 | 0.294 |

| Thermal Expansion | X10-6/°F | 7.2 | 7.4 | 7.7 | |

| Elastic Modulus | psi x 106 | 28.5 | 27.9 | 27.8 | 27.6 |

| Poisson Ratio | 0.29 | 0.29 | 0.29 | 0.3 | |

| Thermal Conductivity | W/ft h °F | 1.5 | 1.8 | 2 | 2.2 |

| Specific Heat | Btu/lb °F | 0.09 | 0.1 | 0.1 | 0.11 |

Superior dimensional control, better surface finish, and the ability to achieve high strength in alloys which cannot be achieved by heat treatment alone.

It is recommended that materials have a PREN > 40 for seawater injection applications.

MIN OD: 2-1/16″ (2.0625″)

MAX OD: 10-3/4″ (10.750”)

MAX WALL THICKNESS: 1.925”

LENGTHS: Up to 70′ (840”) – R1, R2, R3

END FINISH: Plain end, Premium threads, & API threads

Standard & Non-Standard Sizes Available.

Manufactured Material Available as Quickly as 1 Week.

Non-Standard Mill Quantities Accommodated

Our expert metallurgy team is here to help.

Contact Us