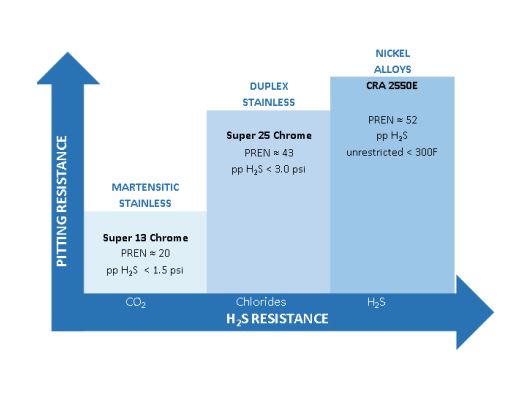

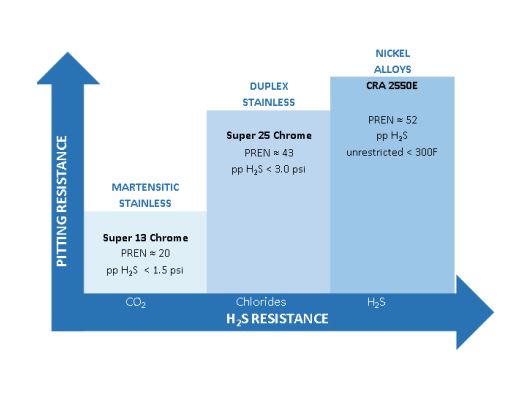

If water is present in acid gases, the conditions may be very corrosive. Low alloy steels are commonly utilized in “dry” Acid Gas Injection wells that are designed to be “water free”. However low compressor discharge temperatures may result in water formation even in dry acid gas wells. Casing and tubing are also exposed to groundwater below the packer. Stainless steels may provide sufficient resistance to corrosion from CO2, however, the partial pressure of H2S in the acid gas often exceeds the limits of stainless steels. In these situations, we recommend using nickel base alloy such as CRA 2550E.

*While every effort has been made to ensure the accuracy of the above review, assessment, conclusions, and report, the appropriateness of their application and their interpretation remain the sole responsibility of the user.

"*" indicates required fields